|

Farmall & IHC Tractors Discussion Board |

300U 12v Conversion Done!!

[ Expand ] [ View Replies ] [ Add a Reply ] [ Return to Forum ]

Posted by JayWalt on March 02, 2007 at 19:58:59 from (70.226.7.125):

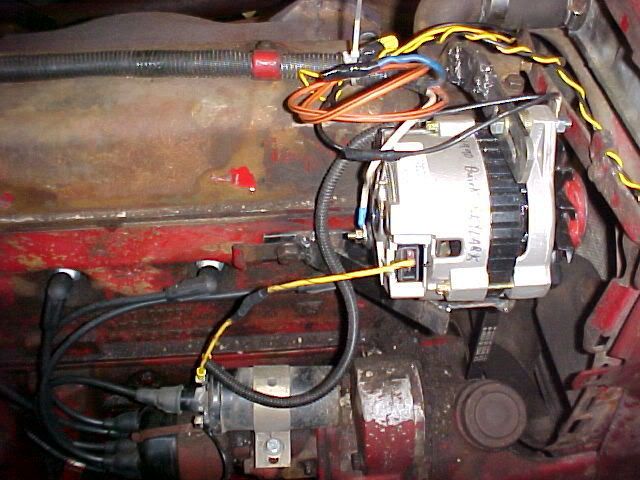

Well guys, I got it done. I used a GM 4 wire alternator. 1 main output, one field input, and one turn on input, and a output for the gauge package. This came off of my 1990 buick skylark. The car was total'd about 3 years ago, breaking the alternaotr mount. I returned it for a new one since it has a lifetime warranty. Now if this one every fails, I just return it and get a new one!!

I made the mount myself. The original genny mount couldnt be used, because it bumped the pivot point too far out and would cause interference with the hood. I could have drilled a hole halfway through the mount and make the pivot there, but one of my promises to myself is to not alter original parts if I dont have to. In doing this, it keeps all part in original condition in case someone would ever need them, or want to restore the tractor. I made the top slider stepped to mount the alternator. My main pivot mount is stout as can be, and I feel it is more then adequate. It was a real pain lining it up tho, heat from welding can warp metal just enough to tick ya off!! =) If I had a wire welder I would have stitch welded it, but doing that with a stick welder is nearly impossible. Now, for the coil, I looked through the 7 my dad had laying around, and the best canditidate connection wise was a nissan coil from an old pickup. enough said. The solenoid, I wanted to address that before it became a problem. I got a ford one from advanced auto. It was a pretty close fit, but turns out not quite good enough without some modification. First, I had to flip it 180, or else the power connector on the starter would hit the frame of the solenoid. So because of that, I had to make a longer copper flat piece to bridge power from the solenoid to the starter.

Now there is about 1" of room between the steering draglink ball end and the solenoid's "I" connector. The pic isnt very accurate from the angle. I dont see that being a problem, If I have that main cast piece break off fromt he steering box, it could hit, but then I got bigger problems then a $13 solenoid.

I removed the regulator and bridged the few connections I needed to.

There is a fusible link between the alternator and solenoid battery term. I also used a 1n5406 between the coil's power connection and the alterntors field and turn on terminals.

The system works great!! now for a new battery for my car, car's old battery into truck, truck battery into tractor =) Bad thing is the car and truck are side post, so I dunno if I'll get new cables or just buy a new battery soley for the tracor, or buy them stupid side to top adapters, havent decided, and for now its got a very underpowered half dead riding lawnmower battery in it. I have a 300AH battery rack in the garage I just jumper from to start it.

The maint mount from below

BTW, the hood does fit, the alternator has proper output voltage at engine idle speed. One thing I had to do was split a pulley because ALL of the alternator pulleys I had (about 13 of them for v belts) wouldnt accomadate my 1/2" spliceable belt. This also made the pulley smaller in diamter too =) (forgot who suggestd it on here, but thanks, nobody else had pulleys that would fit the alternator and my belt, not even the alternator/starter rebuild shop). I hacksawed it in half, then used a dremel tungsten carbide bit in the drill press to flatten out the cut edges and sandwiched a washer between them. The alternator shaft was barely long enough to get 4 turns of the nut on, so I used some loctite on the nut for added security.

Comments are appreciated...

Replies:

Home

| Forums

Today's Featured Article -

Hydraulic Basics - Part 2 - by Curtis Von Fange. In the last entry to this series we gave a brief overview of hydraulic system theory, its basic components and how it works. Now lets take a look at some general maintenance tips that will keep our system operating to its fullest potential. The two biggest enemies to a hydraulic system are dirt and water. Dirt can score the insides of cylinders, spool valves and pumps. Wate

... [Read Article]

Latest Ad:

1964 I-H 140 tractor with cultivators and sidedresser. Starts and runs good. Asking 2650. CALL RON AT 502-319-1952

[More Ads]

Copyright © 1997-2025 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V. Yesterday's Tractors - Antique Tractor HeadquartersWebsite Accessibility Policy |

|